jueves, 9 de septiembre de 2010

domingo, 29 de agosto de 2010

sábado, 28 de agosto de 2010

TUTORIAL DE COMO PIRATEAR PS3

Muchos rumores eran los que indicaban que por fin llegaría el momento en el que estuviera disponible el pirateo de la PS3. Decir que en un primer momento este tutorial sirve tanto para PS3 normal como para la Slim y que aún falta el último tramo del proceso, que es meter el software externo que seguramente estará al caer en los próximos días. Si os parece empezamos:

1º.- Antes que nada deberemos desmontar nuestra PS3.

2º.- Ahora reuniremos estas herramientas y materiales:

- Placa base de nuestra PS3.

- Infectus ModChip. (Para encontrarlo no tenéis más que buscar por Google)

- Cable IDE 30 awg. (Son los cables anchos de los discos duros)

- Estación de soldadura y estaño.

- Epoxy o cualquier otra forma de sujección.

3º.- Echémosle un vistazo a las placas que entrarán en juego:

En primer lugar podemos var aquí la placa Infectus ModChip con las conexiones marcadas en rojo, amarillo y azul:

La placa de nuestra PS3 por detrás:

4º.- Situando el ModChip:

Basándome en que tratamos con una placa europea (en otro caso se puede situar en el mismo u otro sitio, depende de como prefiráis), aconsejo su situación en cualquiera de las dos zonas marcadas, preferiblemente en la de la derecha:

Es muy aconsejable que quede bien sujeto (con epoxy o con cualquier otra cosa, eso si, pensad que en lo que lo ponéis, necesita ventilación).

5º.- Soldando la alimentación:

Una vez situado, en primer lugar con nuestros cables 30 awg (supongamos que son rojos en primer lugar), conectamos la tierra (GND) y el positivo (5V) en los puntos marcados de la parte trasera de la placa:

Y en nuestro ModChip, en la parte inferior junto al USB:

Es aconsejable cablear por el hueco en U que hace en dicho lado, sin preocuparnos demasiado de quedarnos largos, sino más de que al cerrar no estén presionados o tirantes.

6º.- Soldando las flashes:

Soldamos ambas flashes (supongamos un color azul y amarillo) de datos y transferencias, en la parte original de la placa:

Procederemos de esta manera para las conexiones de datos:

Y así para las de transferencia:

Tal que se conecten como indica en la primera imagen (la del ModChip, la parte amarilla y la parte azul):

7º.- Últimas anotaciones:

Para poder realizar las operaciones de flasheo y demás, tendremos que usar un programa, drivers y demás que comentaremos a continuación.

Para esto, es necesario tener la placa a la vista, para poder conectar nuestro cable USB (2.0 sirve) al modchip directamente, y de ahi realizar las operaciones.Aseguraos de tener las conexiones correctas, ya que en algunos casos da errores de lectura y/o escritura, que bien pueden estropear el acceso a las propias flashes.

Es recomendable que sujeteis el cableado con cualquier medio (epoxy o cualquier otro medio) para evitar movimiento dentro, una vez rearmada la consola.

8º.- Flasheando:

Nos bajamos esto e instalamos los drivers en nuestro PC. (Simplemente descargándolo del enlace anterior, descomprimimos y si estamos en Windows presionamos el botón derecho del ratón sobre siusbxp.inf > Instalar, dentro de la carpeta de drivers)

Instalamos el InfectusProgrammer en nuestro PC y conectamos el USB al ModChip, encendemos la PS3 y una vez en el XMB, pudiendo navegar por el menú, conectamos el cable al PC.

Iniciamos el Programmer desde el PC (en este punto está todo conectado ya) y, en el menu, vamos a Actel Firmware >> Double Nand Programmer.

Aparecerá la siguiente imagen si todo ha ido bien:

Ahora updateamos el ModChip siguiendo la siguiente imagen:

Procedemos al flasheo (Importante: NO tocar las conexiones al Modchip en el proceso de lectura/escritura, para evitar datos corruptos.):

- Seleccionar la flash a manejar:

- Leer o dumpear la flash seleccionada (guardándose esta en una localización que elijamos en formato ps3_flashX_1.XX.bin):

- Borrar la flash actual residente (con una confirmación para evitar despistes):

- Escribir con la flash de nuestra elección (que tendremos alojada en nuestro PC):

Este proceso es algo lento, por lo que tened paciencia, una vez finalizado, resetead la consola (apagad y encended) para los cambios. De esta manera, podemos bajar, por ejemplo, de un fw 1.60 a un 1.50 escribiendo su flash

9º.-FAQ Y Consideraciones Finales:

- ¿Al instalar este modchip no podré jugar a juegos originales o perderé alguna funcionalidad? En absoluto, sigues teniendo todas las opciones. Claro está que para no cargarte la consola (y perder todas las funcionalidades) debes tener conocimientos de electrónica e informática.

- ¿Podré actualizar a un fw oficial sin problema? Sí.Aca les dejo un video de como Flashear la Playstation 3 una vez que el Chip esta colocado.

A continuación un vídeo con la última parte del proceso:

Vuelvo a repetir que hasta que no aparezca el flash (la parte software) de este proceso, no podremos piratear nuestra PS3 al 100%, pero seguramente estará al caer, os mantendré informados.

COMO PIRATEAR LA WII SIN CHIP

Tutorial para piratear la Wii sin necesidad de chip. Y es que resulta que es mucho más sencillo de lo que parece en realidad, sólo tenemos que seguir unos sencillos pasos, allá van:

Para poder modificar tu Wii sin necesidad de chip necesitas tener una tarjeta de memoria SD. La tarjeta debe tener 2 Gb o menos (no debe ser SDHC). Aunque pueden funcionar, no recomendamos el uso de tarjetas mini o micro-sd con adaptador.

Este procedimiento es válido para todas las Wiis incluida la wii negra en sus versiones de firmware 3.0, 3.1, 3.2, 3.4, 4.0, 4.1 y 4.2 (en el caso de la 4.2 el inicio de la modificación es un tanto diferente como veremos). En caso de tener una versión inferior a 3.0 basta con que actualices la consola con cualquier juego de esta lista que tenga una versión 3.0 o superior.

PRIMERA PARTE. INSTALACIÓN DEL CANAL HOMEBREW CHANNEL

La instalación de este nuevo canal te permitirá lanzar posteriormente juegos y programas de utilidades. Los 4 primeros pasos son diferente según la versión de Wii que tengas. Es un proceso seguro y, por mucho que te equivoques, no dañarás tu consola.

A) Primeros pasos en versiones desde 3.0 a 4.1

1. Descarga la versión V1 de bannerbomb y descomprímela en la tarjeta SD vacía (te aconsejamos que esté formateada en FAT). Es una sóla carpeta llamada PRIVATE.

2. Descarga el instalador HACKMII v0.6 . Dentro del archivo comprimido encontrarás una carpeta llamada “hackmii_installer_v0.6″ que continene varios archivos. Busca entre estos uno llamado BOOT.ELF y copialo a la raiz de la tarjeta SD. A estas alturas la tarjeta SD debería tener una carpeta llamada PRIVATE y un archivo llamado BOOT.ELF.

3. Saca la tarjeta SD del PC e introdúcela en la Wii. Enciende la Wii y da los siguientes pasos por los menús: OPCIONES DE WII – GESTIÓN DE DATOS – CANALES – Tarjeta SD (pestaña superior derecha).

4. En caso de tener los archivos bien grabados en la SD saltará un cuadro de diálogo: “Load boot.dol/elf?” SÍ / NO. Pulsamos con el botón A sobre SÍ.

(SALTA AL PUNTO 5)

B) Primeros pasos en versión 4.2

1. Descarga la versión V2 de bannerbomb y descomprímela en la tarjeta SD vacía (te aconsejamos que esté formateada en FAT). Es una sóla carpeta llamada PRIVATE.

2. Descarga el instalador HACKMII v0.6 . Dentro del archivo comprimido encontrarás una carpeta llamada “hackmii_installer_v0.6″ que continene varios archivos. Busca entre estos uno llamado BOOT.ELF y copialo a la raiz de la tarjeta SD. A estas alturas la tarjeta SD debería tener una carpeta llamada PRIVATE y un archivo llamado BOOT.ELF.

3. Saca la tarjeta SD del PC e introdúcela en la Wii. Enciende la Wii y pulsa con el botón A señalando al dibujo de la tarjeta SD (MENÚ TARJETA SD). Si fura la primera vez que usas este menú tendrás que pasar los mensajes de bienvenida.

4. En caso de tener los archivos bien grabados en la SD saltará un cuadro de diálogo: “Load boot.dol/elf?” SÍ / NO. Pulsamos con el botón A sobre SÍ.

5. Tras unos instantes aparecerá un mensaje sobre el copyrigt del programa. Hay que esperar unos segundos para que aparezca “PRESS 1 TO CONTINUE”. Pulsamos el botón 1. A continuación se mostrará el menú del INSTALADOR HACKMII. Para esta instalación no son relevantes dichos mensajes, ya que no vamos a realizar operaciones avanzadas.

6. Verás resaltada la palabra CONTINUE. Pulsa el botón A para pasar a la siguiente pantalla.

7. Usando la cruz del mando escogemos la opción INSTALL THE HOMEBREW CHANNEL y pulsamos el botón A. A continuación pedirá nuestra confirmación. Seleccionaremos la opción <YES, CONTINUE> y volvemos a pulsar el botón A. Si todo ha ido bien aparecerá la palabra SUCCESS. y la palabra CONTINUE resalatada. Pulsa el botón A para volver al menú anterior.

8. A continuación, siguiendo el mismo procedimiento, instalamos DVDx. Esto es necesario para ciertas funciones de algunos programas y emuladores.

9. Una vez instalado DVDx seleccionamos EXIT y pulsamos el botón A. La opción Bootmii no es necesaria para este tipo de instalación.

A continuación aparecerá el HOMBREW CHANNEL, un nuevo canal que te permitirá lanzar juegos y programas. Por el momento está vacío.

SEGUNDA PARTE. INSTALACIÓN DE JUEGOS Y PROGRAMAS

Ya puedes borrar por completo tu tarjeta SD.

Para instalar juegos caseros y programas deberás crear una carpeta en la raiz de la tarjeta SD con el nombre “apps”. En su interior grabarás las carpetas de los juegos y programas que quieras usar.

A continuación te mostramos enlaces a juegos emuladores, y programas:

A continuación te mostramos enlaces a juegos emuladores, y programas:

JUEGOS:

Puedes descargarlos AQUÍ:

Te recomendamos el juego SUPER MARIO WARPuedes descargarlos AQUÍ:

EMULADORES:

Puedes descargarlos de AQUÍ

JUEGOS PARA EMULADORES:

Puedes descargarlos de AQUÍ

PROGRAMAS:

Puedes descargarlos de AQUÍ

Te recomendamos HOMEBREW BROWSER. Es una aplicación de Wii que te permite descargar automáticamente desde la misma Wii otras aplicaciones y juegos.

TERCERA PARTE. CARGAR JUEGOS Y PROGRAMAS

Una vez hayas grabado los juegos y programas en tu tarjeta SD, respetando la estructura comentada anteriormente, debes dejar intriducida la tarjeta en la consola para poder usarlos.

Para cargar cualquier juego o aplicación instalada:

1. Pulsa A sobre el canal HOMEBREW CHANNEL y dale a COMENZAR

2. Pulsa A sobre el juego y después a CARGAR.

Con esto ya estaremos jugando a nuestros juegos favoritos con nuestra Wii pirateada y sin chip.

CARGA DE COPIAS DE SEGURIDAD DE JUEGOS DE Wii

Para poder cargar copias de seguridad de juegos de Wii se necesitan hacer algunas instalaciones de software adicionales (softmod) o instalar un modchip.

Nosotros te recomendamos que cuentes con profesionales en la modificación de tu Wii, para que te faciliten una instalación que se adapte a tu modelo y versión de Wii , programas y manuales para usar tus backups, garantía en la instalación, software/hardware actualizado, soporte, etc. (puedes contactar si lo deseas con alguno de nuestros patrocinadores).

COMO HACER UN AEROGENERADOR

Como hacer un aerogenerador, turbina eolica o molino de viento.

Para hacer un aerogenerador es muy importante la turbina eólica que puede variar según el tipo de motor o generador que le instalemos, pero normalmente será de unos 12v de tensión eficiente.

Para hacer un aerogenerador es muy importante la turbina eólica que puede variar según el tipo de motor o generador que le instalemos, pero normalmente será de unos 12v de tensión eficiente.

Después de muchas búsquedas de información por todo Internet, todos los diseños tenían cinco cosas en común:

- Un generador.

- Palas.

Sistema de orientación hacia el viento (Timón).- Una torre para elevar la turbina hacia dónde esté el viento.

- Baterías y un sistema de control eléctrico.

Organizando un poco el tema, conseguí reducir el proyecto a tan sólo cinco sistemas, que atacando poco a poco y uno por uno, no resulta del todo complicado. Decidí comenzar con el generador. Observando los proyectos de otras personas por Internet, me dí cuenta que había gente que decidió hacerse su propio generador, otros que usaban la energía residente de motores de imán permanente, y otros, simplemente se buscaban un generador. Así que decidí ponerme a buscar.

Mucha gente usaban los motores de las unidades de cinta de ordenadores antiguos. Los mejores para esto, son los Ametek de 99 voltios en continua que funcionan muy bien como generadores. Por desgracia, son muy difíciles de encontrar, aunque siempre puedes probar con otros modelos parecidos de Ametek.

Existen muchas otras marcas y modelos de motores de imán permanente que no sean los Ametek, pero puede que no trabajen igual de bien, ten en cuenta que los motores de imán permanente no fueron diseñados para ser generadores. Los motores normales, cuando se usan como generadores, tienen que ser impulsados mucho más rápido que su velocidad nominal de funcionamiento para alcanzar una producción parecida a la de su funcionamiento normal. Con estos datos, podemos sacar una conclusión, lo que estamos buscando, es un motor que de mucha tensión con pocas revoluciones. Alejarse de motores con muchas revoluciones y poca tensión, porque no servirá para nada. Lo que buscamos, más o menos, es un motor que nos de unos 12 v de tensión útil con unas revoluciones muy bajas (325 rpm). Cuando lo tengáis, para hacer la prueba, conectarlo a una bombilla de 12 v y darle un fuerte giro al motor con la mano, si de verdad nos funciona, la bombilla deberá encenderse como normalmente.

He conseguido unos motores Ametek que funcionan a 30 v en Ebay por sólo 26 $. Hoy día se están abaratando debido a que mucha gente los compra para hacerse sus propios molinos de viento.

Me puse a investigar un poco más para las palas. Vi que mucha gente talla sus propias palas en madera, pero eso es demasiado complicado, teniendo en cuenta que otras personas hacían sus palas con tubos de PVC con el mismo resultado.

Seguí más o menos la guía cambiando unas cuantas cosas. Usé una tubería ABS negra que venían ya precortadas. Usé la tubería de 6 pulgadas de diámetro en vez de 4 y 24 pulgadas de largo en vez de 19 5/8. La diferencia está en que pesará un poco más, pero las revoluciones serán mayores también a recoger más viento, y ganaremos un poco de energía.

Empecé marcando y cortando el tubo longitudinalmente en cuatro piezas iguales, corté una y la usé como guía para el resto, limando los bordes y pesándolas si es necesario para evitar descompensar el aparato. Finalmente, terminé con 4 palas, tres para usarlas y una de repuesto. Para mejorar la aerodinámica se pueden limar los bordes como cuchillas para que “corte” el viento y obtenga una menor resistencia.

El siguiente paso era unir las palas al motor, para lo que usé unos pernos. Por mi taller apareció una rueda dentada que encajaba a la perfección en el eje del motor, pero no tenía ni los agujeros necesarios, ni el diámetro para hacer la unión perfecta con las palas, así que le añadí un disco de aluminio de 5 pulgadas de diámetro y ¼ pulgada de grosor que valía perfectamente para la unión de las palas. La solución fácil de esto fue unir ambas piezas y dejarlas fijas completamente.

Esta es la perforación y grabación de las piezas.

Las piezas armadas, incluyendo las palas.

La otra parte del ensamble completo.

En uno de mis viajes a la ferretería, encontré esta tapa que viene perfecta para la punta de las aspas, evitando así la resistencia del aparato al viento y repartiendo más aire aún hacia las palas.

Actualización: Más adelante, en un día de muchísimo viento, se me partieron las aspas del aerogenerador, y opté por hacerle este cambio, perdía en longitud, pero ganaba en resistencia. Para no prescindir de ninguna, debéis hacerlo así desde el principio.

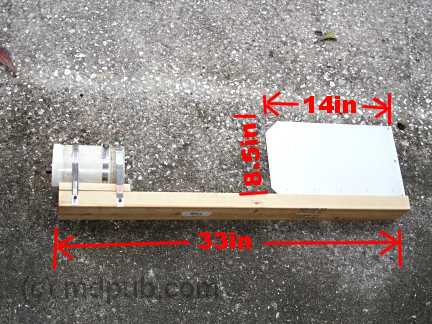

Lo siguiente era el montaje del esqueleto de la turbina, para hacerlo sencillo, opté por colocar el motor en un trozo de madera de 2 X 4 pulgadas agarrado con unas abrazaderas ajustables. También, para proteger un poco el motor, lo puse dentro de un tubo de PVC que tenía su diámetro justo. Le coloqué una cola para direccionar el esqueleto hacia el viento, la mía estaba hecha de aluminio rígido y tenía las dimensiones que están en la imagen, aunque eso no es algo que deba preocuparos.

Esta es otra vista del esqueleto de la turbina de viento.

El siguiente paso fue pensar en algún tipo de mecanismo que permitiera girar libremente a la turbina según la dirección en la que viniera el viento. Después de mucho pensar, me di cuenta que con una barra de metal de 1 pulgada de diámetro y 10 de largo introducida en un tubo de acero de 1 pulgada y 1/4 de diámetro, funcionaba a la perfección. Usaría por ambos lados los tubos de acero de 1 pulgada, y de cuerpo o torre, usaría el de 1 pulgada y 1/4. Para elegir la posición del tubo de acero, miré el esqueleto y calculé el centro de gravedad, tan simple como ver el sitio de la madera (la de 33 pulgadas) dónde se queda en equilibrio. Los cables del generador, pasarán por un agujero por el centro del tubo de sujeción.

Para la base de la torre, corté una base de 2 pies de diámetro de madera contrachapada. Le hice un montaje en forma de U con tuberías de 1 pulgada que es dónde iría el otro extremo del tubo o torre de 1 pulgada y ¼ de diámetro. Como la parte superior, es libre de girar para dónde quiera también, así se le da más movilidad por si en un momento dado se atasca la de arriba. También la U es movible en forma de bisagra para facilitar la subida y bajada de la turbina de viento. Entre la U y el tubo de 1 pulgada, añadí una T con un agujero para poder sacar por ahí el cable. Eso se muestra en una foto de abajo. También incluiré unos agujeros en la madera contrachapada para poner unos anclajes para el suelo.

Esta foto muestra la cabeza y la base juntos. Ahora te puedes hacer a la idea de como irá quedando, imagínate una tubería de 10 pies entre los extremos.

Después pinté todas las piezas de madera con una pintura protectora blanca. En esta foto se ve también un añadido en la cola, es un pedazo de plomo para contrapesar.

Aquí está todo el conjunto de la cabeza.

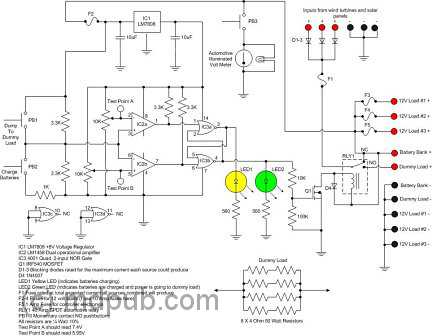

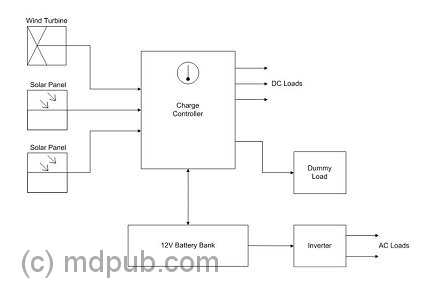

Después de tener listo toda la parte de mecánica, decidí ponerme con la electrónica. El sistema estaría compuesto por un sistema de una o varias baterías para almacenar la energía acumulada por el aerogenerador, un diodo de bloqueo para evitar el desperdicio de energía desde las baterías, una carga secundaria para tirar la energía que sobre cuando las baterías estén totalmente cargadas y un controlador de carga para manejarlo todo.

Decidí buscar por Google un poco de información de controladores de carga de aerogeneradores.

Como en esa web explica muy bien la creación de dicho circuito, yo sólo tocaré aspectos generales del mismo.

El principio básico del funcionamiento del controlador es controlar si la batería está cargada para enviar corriente desde la turbina hacia ellas o desviarla hacia una carga para no dañar las baterías. En el link está todo muy bien explicado.

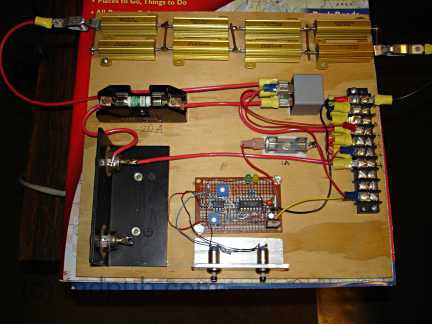

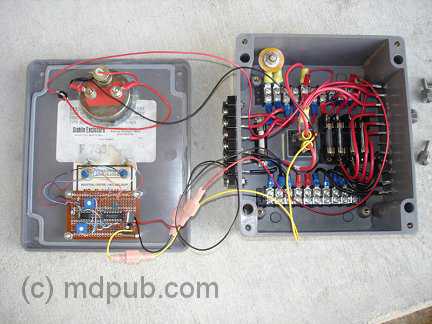

Esta es una foto del controlador construido, está todo en un tablón de madera contrachapada para poder hacer pruebas y arreglar errores. Más tarde lo ensamblaré todo en una caja.

Se puede ver perfectamente la placa de circuito impreso dónde encontramos la electrónica compleja. Un soporte plateado con dos interruptores que permiten alternar entre las baterías y la carga.

El disipador negro de abajo a la izquierda tiene dos diodos de bloqueo de 40 A. Uso sólo uno de momento, pero podría usar el otro para otro aerogenerador o para añadir un panel solar, quién sabe. La doble hilera de rectángulos color dorado de la parte superior es la carga, compuesto por resistencias de alta potencia, a intervalos de 2 Ohm. Sirve para volcar la energía cuando las baterías están cargadas o para hacer pruebas con la turbina. El exceso de potencia de la turbina puede ser aprovechado para un calentador o incluir una segunda batería. Debajo a la izquierda de las resistencias, nos encontramos un fusible, el principal, junto con un relé cuadrado de color gris de 40 A, está sacado de un coche. Es el encargado de enviar la energía o a las baterías o a la carga. Por todo el lado derecho, se pueden ver, en color negro, todas las conexiones en un bloque de terminales.

Operando, la turbina de viento, está conectada a la controladora. Después pasa de la controladora a la batería. Todas las cargas son tomadas de las baterías. Si el voltaje de la batería baja de 11,9 v, el controlador cambia la turbina hacia las baterías. Si el voltaje de la batería se eleva a 14 v, el controlador cambia la turbina hacia la carga. Si te fijas, verás potenciometros para ajustar los voltajes de ambos estados. Elegí 11,9 v para cuando está descargada y 14 v para cuando está cargada debido al asesoramiento encontrado en diferentes sitios web sobre la carga óptima de baterías de plomo-ácido. Cuando el voltaje de la batería está entre 11,9 v y 14 v, el sistema se puede cambiar manualmente a cualquiera de los dos estados. Normalmente, el sistema es automático. Cuando se está utilizando la carga, el LED verde se enciende, cuando se está cargando la batería, es el amarillo el que se enciende. Esto permite tener un mínimo de información del sistema, también uso el polímetro tanto para medir el voltaje de la batería como el de la salida de la turbina. Más adelante añadiré unos medidores de tensión y lo meteré todo en una caja un poco más decente.

Utilicé una fuente de alimentación de voltaje variable para realizar las pruebas de los diferentes estados de la batería (el de 11,9 v y el de 14 v) y así poder ajustar los potenciómetros a mi gusto.

Actualización: Al final cambié el voltaje de derivación a la carga de 14 a 14,8 v, parece que va mejor para la carga de este tipo de baterías.

Actualización: Descubrí que existe un orden para conectar las cosas al controlador y no dañar nada. Una vez conecté la turbina y el panel solar antes que las baterías, y debido a las oscilaciones de tensión, el relé y los voltajes empezaron a hacer cosas raras debido a que no estaba la batería para estabilizar, también se puede dañar el circuito. Lo que se debe hacer siempre es conectar primero las baterías y luego el aerogenerador o el panel solar. Para desconectar es igual, primero se desconectan los sistemas (panel y turbina) y luego las baterías.

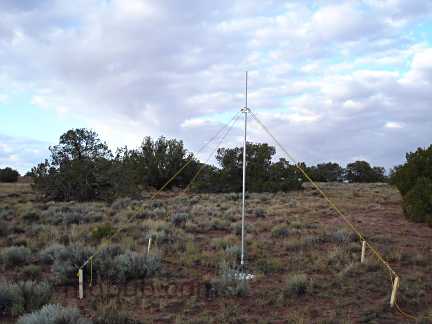

Cuando llegué a mi finca, lo primero que hice fue empezar con el refuerzo de la torre, coloqué la cabeza de la turbina en la tubería de 10 pies de largo y 1 pulgada ¼ de diámetro y la base en el final del mismo. A partir de aquí fue todo muy rápido. Utilicé cuerdas de nylon para sujetar el palo de 10 pies al suelo con estacas de madera y unos tensores en los extremos. Gracias a la bisagra de la base, pude bajar y subir la torre fácilmente. Cuando esté todo andando, las cuerdas de nylon y las estacas de madera se sustituyen por cables de acero y estacas de metal.

En esta foto se muestra de cerca la forma en la que amarré las cuerdas a la tubería de metal. Sencillo a la vez que eficaz.

Esta otra foto muestra la base de la torre, apoyada en el suelo, y con la salida del cable de la turbina por la sección en forma de T. El cable utilizado es un cable normal de instalaciones eléctricas, simplemente cortar y conectar turbina con controlador.

Esta foto muestra la cabeza de la turbina instalada en la parte superior de la torre. Engrasé todo el tubo de la parte inferior de la cabeza y se deslizo solo hasta el tope final.

Solo queda esperar a que sople el viento y empiece a producir.

La turbina funcionando a las mil maravillas, incluso con viento flojo.

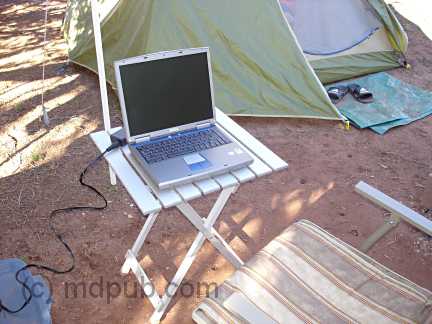

Aquí todo el tinglado de controlador, batería y la electrónica de los cableados. Se puede ver también un inversor de 120 v conectado a la batería y a un polímetro para realizar el seguimiento de la tensión de la batería y de la salida de la turbina. Mi afeitadora eléctrica y el cargador de la batería están conectados al inversor funcionando a 120 v. Más tarde lancé también un cable a mi campamento.

En esta foto, toda la electrónica. El polímetro muestra una producción de 13,32 v, la carga la proporciona la afeitadora y las baterías a través del inversor.

Aquí el polímetro muestra una producción de 13,49 v. La tensión de la turbina sube un poco a la vez que la fuerza del viento, es debido a tener una carga. Cuando gira muy rápidamente y la tensión de la batería es excedida, el diodo se encarga del bloqueo. Cuando se supera el límite, de repente le entra la carga (resistencias) a la turbina. Una de las precauciones a tener en cuenta es tener cuidado con los cambios en la dirección del viento cuando se está trabajando con los cables, ya que podrías partirlos.

Me dí cuenta que toda la configuración del controlador era demasiado peligroso. Ordené un poco los cables y puse toda la electrónica encima de un pedazo de madera en la parte superior de una caja de plástico. Después coloqué un largo cable desde el inversor hasta mi campamento, así era más seguro.

Otra vista más de la configuración.

Aquí mi portátil funcionando gracias a la turbina.

¿Cuanto costó todo?, aquí tenéis una tabla.

| ¿El qué? | ¿De dónde? | ¿Cuanto? |

| Motor / generador. | Ebay. | $26,00 = 18,27€ |

| Varios de tubería. | Ferretería. | $41,49 = 29,16€ |

| Tubería para las palas. | Ferretería. | $12,84 = 9,02€ |

| Varios equipos. | Ferretería. | $8,00 = 5,6€ |

| Conductos. | Ferretería. | $19,95 = 14,02€ |

| Madera y aluminio. | Montón de chatarra | $0,00 |

| Cable de alimentación | Ya lo tenía. | $0,00 |

| Cuerda y tensores. | Ferretería. | $18,47 = 12,98€ |

| Piezas electrónicas | Ya lo tenía. | $0,00 |

| Relé | Almacén de coches. | $13,87 = 9,74€ |

| Batería. | Cogida de mi UPS. | $0,00 |

| Inversor | Ya lo tenía. | $0,00 |

| Pintura | Ya lo tenía. | $0,00 |

| Total | $140,62 = 98,84€ |

No está mal. Teniendo en cuenta que las turbinas profesionales comparables a esta valen entre 750 y 1000 $.

Modificaciones y mejoras que me gustaría hacerle en el futuro:

- Montar los componentes electrónicos en una caja estanca.- Añadir medidores para la tensión de la batería y la de la turbina.- Añadir un tacómetro para saber lo rápido que está girando.- Añadir más baterías.- Añadir otra turbina de viento u otro panel solar para producir más energía.- Obtener un inversor de mayor voltaje.- Sistema de frenado de emergencia para cuando hayan vientos fuertes.- Base de hormigón para la torre.- Una torre más alta con cables y estacas de acero.

Terminé la reconstrucción del controlador. Ahora está en un recinto semiestanco y le he añadido un medidor de tensión. Consta con entradas para varias fuentes y diferentes salidas de cargas externas.

Estas son las entradas del controlador, dos entradas para paneles solares y una para el molino de viento. Esta configuración puede variar a cada gusto.

Esta foto muestra las salidas del controlador. Hay conexiones para las baterías, para la carga y para 3 salidas de 12 v.

Este es el interior del controlador, básicamente transferí todo lo que había en el tablero de madera hacia aquí. He añadido un medidor de voltaje y un fusible por cada salida.

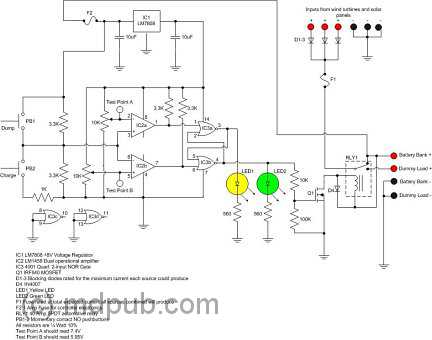

Este es el esquema del nuevo controlador, es casi igual que el antiguo a excepción de los dos cambios que dije anteriormente.

Este diagrama de bloque da una visión general de lo que es el montaje.

La versión original se puede ver en:

http://www.mdpub.com/Wind_Turbine/

que tiene el siguiente contenido:

La versión original se puede ver en:

http://www.mdpub.com/Wind_Turbine/

que tiene el siguiente contenido:

Several years ago I bought some remote property in Arizona. I am an astronomer and wanted a place to practice my hobby far away from the sky-wrecking light pollution found near cities of any real size. I found a great piece of property. The problem is, it's so remote that there is no electric service available. That's not really a problem. No electricity equals no light pollution. However, it would be nice to have at least a little electricity, since so much of life in the 21st century is dependent on it. Several years ago I bought some remote property in Arizona. I am an astronomer and wanted a place to practice my hobby far away from the sky-wrecking light pollution found near cities of any real size. I found a great piece of property. The problem is, it's so remote that there is no electric service available. That's not really a problem. No electricity equals no light pollution. However, it would be nice to have at least a little electricity, since so much of life in the 21st century is dependent on it. One thing I noticed right away about my property is that most of the time, the wind is blowing. Almost from the moment I bought it, I had the idea of being energy independent by putting up a wind turbine and making some electricity, and later adding some solar panels and a wood gasifier. This is the story of how I did it. Not with an expensive, store-bought turbine, but with a home-built one that cost hardly anything. If you have some fabricating skills and some electronic know-how, you can build one too. Let me state up front that I probably won't be able to help you out much if you decide to build your own wind turbine. This web site has become insanely popular, often taxing the bandwidth limits of the server. I get dozens of requests for help each day. I simply don't have time to answer the majority of them. Most of the questions and requests I get are the same ones over and over again. I have crated a FAQ to handle these repetitive questions. Please read it before emailing me. Simple questions, not covered by the FAQ, which only require a quick and simple answer may get replies if time permits. However, there is no way I can help you out with complex issues, teach you electronics theory, help you locate parts, build a charge controller for you, or custom design a system for you. There just aren't enough hours in the day. Sorry. Since no one seems to be reading the FAQ, I will answer the No. 1 question I get many, many times a day right here up front. Why didn't I just use an automotive alternator on my wind turbine? Automotive alternators need to spin at very high speed to produce useful amounts of power. Most wind turbines don't spin fast enough for them to work. Update: Here is a video of the wind turbine in operation. Update: Here is a video of me assembling and setting up the wind turbine on my remote off-grid property. I started the process of designing my wind turbine by Googling for information on home-built wind turbines. There are a lot of them out there in an amazing variety of designs and complexities. All of them had five things in common though:

A lot of people seemed to like to use old computer tape drive motors (surplus relics from the days when computers had big reel to reel tape drives). The best apparently are a couple of models of motor made by Ametek. The best motor made by Ametek is a 99 volt DC motor that works great as a generator. Unfortunately, they are almost impossible to locate these days. There are a lot of other Ametek motors around though. A couple of their other models make decent generators and can still be found on places like Ebay http://www.tlgwindpower.com/ametek.htm There are probably lots of other brands and models of permanent magnet DC motors available that will work well as generators. Permanent magnet DC motors work as generators, but they weren't designed to be generators. So they aren't great generators. Some types of motor are a lot worse than others. When used as generators, motors generally have to be driven far faster than their rated speed to produce anything near their rated voltage. So what you are looking for is a motor that is rated for high DC voltage, low rpms and high current. Steer away from low voltage and/or high rpm motors. You want a motor that will put out over 12 Volts at a fairly low rpm, and a useful level of current. So a motor rated for say 325 rpm at 30 Volts when used as a generator, could be expected to produce 12+ volts at some reasonably low rpm. On the other hand, a motor rated at 7200 rpm at 24 volts probably won't produce 12+ volts as a generator until it is spinning many thousands of rpm, which is way too fast for a wind turbine. So shop for motors accordingly. They don't go that cheap these days. People are catching on to the fact that they make great wind generators. Other brands will work, so don't fret about the price Ameteks are going for. Shop wisely. Anyway, The motor I got was in good shape and worked great. Even just giving the shaft a quick turn with my fingers would light a 12 volt bulb quite brightly. I gave it a real test by chucking it up in my drill press and connecting it to a dummy load. It works great as a generator, putting out easily a couple hundred Watts with this setup. I knew then that if I could make a decent set of blades to drive it, it would produce plenty of power. So Blades and a hub to connect them to were the next order of business. More online research ensued. A lot of people made their own blades by carving them out of wood. That looked like an outrageous amount of work to me. I found that other people were making blades by cutting sections out of PVC pipe and shaping them into airfoils. That looked a lot more promising to me. This web site tells you how to make a set of blades for a small wind turbine using PVC pipe. http://www.yourgreendream.com/diy_pvc_blades.php  I followed their general recipe. I did things a little differently though. I used black ABS pipe since my local homecenter store just happened to have pre-cut lengths of it. I used 6 inch pipe instead of 4 inch and 24 inches long instead of 19 5/8. I started by quartering a 24 inch long piece of pipe around its circumference and cutting it lengthwise into four pieces. Then I cut out one blade, and used it as a template for cutting out the others. That left me with 4 blades (3 plus one spare). I followed their general recipe. I did things a little differently though. I used black ABS pipe since my local homecenter store just happened to have pre-cut lengths of it. I used 6 inch pipe instead of 4 inch and 24 inches long instead of 19 5/8. I started by quartering a 24 inch long piece of pipe around its circumference and cutting it lengthwise into four pieces. Then I cut out one blade, and used it as a template for cutting out the others. That left me with 4 blades (3 plus one spare).  I then did a little extra smoothing and shaping using my belt sander and palm sander on the cut edges to try to make them into better airfoils. I don't know if it's really much of an improvement, but it didn't seem to hurt, and the blades look really good (if I do say so myself). I then did a little extra smoothing and shaping using my belt sander and palm sander on the cut edges to try to make them into better airfoils. I don't know if it's really much of an improvement, but it didn't seem to hurt, and the blades look really good (if I do say so myself). Now I needed a hub to bolt the blades to and attach to the motor. Rummaging around in my workshop, I found a toothed pulley that fit on the motor shaft, but was a little too small in diameter to bolt the blades onto. I also found a scrap disk of Aluminum 5 inches in diameter and ¼ inch thick that I could bolt the blades onto, but wouldn't attach to the motor shaft. The simple solution of course was to bolt these two pieces together to make the hub. Now I needed a hub to bolt the blades to and attach to the motor. Rummaging around in my workshop, I found a toothed pulley that fit on the motor shaft, but was a little too small in diameter to bolt the blades onto. I also found a scrap disk of Aluminum 5 inches in diameter and ¼ inch thick that I could bolt the blades onto, but wouldn't attach to the motor shaft. The simple solution of course was to bolt these two pieces together to make the hub.  Much drilling, tapping and bolting later, I had a hub. Much drilling, tapping and bolting later, I had a hub. Here it is assembled and with the blades attached (after drilling mounting holes in them of course). Here it is assembled and with the blades attached (after drilling mounting holes in them of course). Here is another view of the hub with blades attached. Here is another view of the hub with blades attached. On a trip to the homecenter store for some PVC doo-dad or other for another project, I found these dome shaped vent caps. On a trip to the homecenter store for some PVC doo-dad or other for another project, I found these dome shaped vent caps.  I immediately thought of adding a spinner to the hub. Wow, with that on there, it really looks like a professionally made unit. I'd never be able to convince anyone I built it myself out of junk from my workshop and plumbing parts. They'd all look at me when I said I built it myself and go "Yeah, right." Then I found a web site that claimed such spinners disrupt the airflow and hurt the efficiency of the blades. I'm not sure I believe the reasoning behind the claim, but I left the spinner off, at least initially. I immediately thought of adding a spinner to the hub. Wow, with that on there, it really looks like a professionally made unit. I'd never be able to convince anyone I built it myself out of junk from my workshop and plumbing parts. They'd all look at me when I said I built it myself and go "Yeah, right." Then I found a web site that claimed such spinners disrupt the airflow and hurt the efficiency of the blades. I'm not sure I believe the reasoning behind the claim, but I left the spinner off, at least initially. Next I needed a mounting for the turbine. Keeping it simple, I opted to just strap the motor to a piece of 2 X 4 wood. The correct length of the wood was computed by the highly scientific method of picking the best looking piece of scrap 2 X 4 off my scrap wood pile and going with however long it was. I also cut a piece of 4 inch diameter PVC pipe to make a shield to go over the motor and protect it from the weather. For a tail to keep it turned into the wind, I again just used a piece of heavy sheet Aluminum I happened to have laying around. I was worried that it wouldn't be a big enough tail, but it seems to work just fine. The turbine snaps right around into the wind every time it changes direction. For those of you always clamoring for me to provide plans, blueprints, schematics, etc., for my projects, I have added a few dimensions to the picture. I doubt any of these measurements is critical though. Next I needed a mounting for the turbine. Keeping it simple, I opted to just strap the motor to a piece of 2 X 4 wood. The correct length of the wood was computed by the highly scientific method of picking the best looking piece of scrap 2 X 4 off my scrap wood pile and going with however long it was. I also cut a piece of 4 inch diameter PVC pipe to make a shield to go over the motor and protect it from the weather. For a tail to keep it turned into the wind, I again just used a piece of heavy sheet Aluminum I happened to have laying around. I was worried that it wouldn't be a big enough tail, but it seems to work just fine. The turbine snaps right around into the wind every time it changes direction. For those of you always clamoring for me to provide plans, blueprints, schematics, etc., for my projects, I have added a few dimensions to the picture. I doubt any of these measurements is critical though. Here is another view of the completed head of the unit with the motor and tail attached. Here is another view of the completed head of the unit with the motor and tail attached. Next I had to begin thinking about some sort of tower and some sort of bearing that would allow the head to freely turn into the wind. I spent a lot of time in my local homecenter stores (Lowes and Home Depot) brainstorming. Finally, I came up with a solution that seems to work well. While brainstorming, I noticed that 1 inch diameter iron pipe is a good slip-fit inside 1 1/4 inch diameter steel EMT electrical conduit. I could use a long piece of 1 1/4 inch conduit as my tower and 1 inch pipe fittings at either end. For the head unit I attached a 1 inch iron floor flange centered 7 1/2 inches back from the generator end of the 2X4, and screwed a 10 inch long iron pipe nipple into it. The nipple would slip into the top of the piece of conduit I'd use as a tower and form a nice bearing. Wires from the generator would pass through a hole drilled in the 2X4 down the center of the pipe/conduit unit and exit at the base of the tower. Brilliant! (if I do say so myself) Next I had to begin thinking about some sort of tower and some sort of bearing that would allow the head to freely turn into the wind. I spent a lot of time in my local homecenter stores (Lowes and Home Depot) brainstorming. Finally, I came up with a solution that seems to work well. While brainstorming, I noticed that 1 inch diameter iron pipe is a good slip-fit inside 1 1/4 inch diameter steel EMT electrical conduit. I could use a long piece of 1 1/4 inch conduit as my tower and 1 inch pipe fittings at either end. For the head unit I attached a 1 inch iron floor flange centered 7 1/2 inches back from the generator end of the 2X4, and screwed a 10 inch long iron pipe nipple into it. The nipple would slip into the top of the piece of conduit I'd use as a tower and form a nice bearing. Wires from the generator would pass through a hole drilled in the 2X4 down the center of the pipe/conduit unit and exit at the base of the tower. Brilliant! (if I do say so myself) For the tower base, I started by cutting a 2 foot diameter disk out of plywood. I made a U shaped assembly out of 1 inch pipe fittings. In the middle of that assembly I put a 1 1/4 inch Tee. The Tee is free to turn around the 1 inch pipe and forms a hinge that allows me to raise and lower the tower. I then added a close nipple, a 1 1/4 to 1 reducing fitting, and a 12 inch nipple. Later I added a 1 inch Tee between the reducer and the 12 inch nipple so there would be a place for the wires to exit the pipe. This is shown in a photo further down the page. I also later drilled holes in the wooden disk to allow me to use steel stakes to lock it in place on the ground. For the tower base, I started by cutting a 2 foot diameter disk out of plywood. I made a U shaped assembly out of 1 inch pipe fittings. In the middle of that assembly I put a 1 1/4 inch Tee. The Tee is free to turn around the 1 inch pipe and forms a hinge that allows me to raise and lower the tower. I then added a close nipple, a 1 1/4 to 1 reducing fitting, and a 12 inch nipple. Later I added a 1 inch Tee between the reducer and the 12 inch nipple so there would be a place for the wires to exit the pipe. This is shown in a photo further down the page. I also later drilled holes in the wooden disk to allow me to use steel stakes to lock it in place on the ground.  This photo shows the head and base together. You can begin to see how it will go together. Imagine a 10 foot long piece of steel conduit connecting the two pieces. Since I was building this thing in Florida, but was going to use it in Arizona, I decided to hold off on purchasing the 10 foot piece of conduit until I got to Arizona. That meant the wind turbine would never be fully assembled and not get a proper test until I was ready to put it up in the field. That was a little scary because I wouldn't know if the thing actually worked until I tried it in Arizona. This photo shows the head and base together. You can begin to see how it will go together. Imagine a 10 foot long piece of steel conduit connecting the two pieces. Since I was building this thing in Florida, but was going to use it in Arizona, I decided to hold off on purchasing the 10 foot piece of conduit until I got to Arizona. That meant the wind turbine would never be fully assembled and not get a proper test until I was ready to put it up in the field. That was a little scary because I wouldn't know if the thing actually worked until I tried it in Arizona. Next, I painted all the wooden parts with a couple of coats of white latex paint I had leftover from another project. I wanted to protect the wood from the weather. This photo also shows the lead counterweight I added to the left side of the 2X4 under the tail to balance the head. Next, I painted all the wooden parts with a couple of coats of white latex paint I had leftover from another project. I wanted to protect the wood from the weather. This photo also shows the lead counterweight I added to the left side of the 2X4 under the tail to balance the head.  This photo shows the finished head unit with the blades attached. Is that a thing of beauty or what? It almost looks like I know what I'm doing. This photo shows the finished head unit with the blades attached. Is that a thing of beauty or what? It almost looks like I know what I'm doing. I never got a chance to properly test the unit before heading to Arizona. One windy day though, I did take the head outside and hold it high up in the air above my head into the wind just to see if the blades would spin it as well as I had hoped. Spin it they did. In a matter of a few seconds it spun up to a truly scary speed (no load on the generator), and I found myself holding onto a giant, spinning, whirligig of death, with no idea how to put it down without getting myself chopped to bits. Fortunately, I did eventually manage to turn it out of the wind and slow it down to a non-lethal speed. I won't make that mistake again. Now That I had all the mechanical parts sorted out, it was time to turn toward the electronic end of the project. A wind power system consists of the wind turbine, one or more batteries to store power produced by the turbine, a blocking diode to prevent power from the batteries being wasted spinning the motor/generator, a secondary load to dump power from the turbine into when the batteries are fully charged, and a charge controller to run everything. There are lots of controllers for solar and wind power systems. Anyplace that sells alternative energy stuff will have them. There are also always lots of them for sale on Ebay http://www.fieldlines.com/story/2004/9/20/0406/27488 That web site goes into a lot of detail about the controller, so I'm only going to talk about it in fairly general terms here. Again, while I followed their general recipe, I did do some things differently. Being an avid electronics tinkerer from an early age, I have a huge stock of electronic components already on hand, so I had to buy very little to complete the controller. I substituted different components for some parts and reworked the circuit a little just so I could use parts I already had on hand. That way I had to buy almost nothing to build the controller. The only part I had to buy was the relay. Whether you build your own, or buy one, you will need some sort of controller for your wind turbine. The general principal behind the controller is that it monitors the voltage of the battery(s) in your system and either sends power from the turbine into the batteries to recharge them, or dumps the power from the turbine into a secondary load if the batteries are fully charged (to prevent over-charging and destroying the batteries). The schematic and write-up on the above web page does a good job of explaining it.  This is a picture of the controller I built. Click on it to see a larger picture. I just bolted everything to a piece of plywood for testing purposes. Eventually I will mount it in a weather-proof enclosure. This is a picture of the controller I built. Click on it to see a larger picture. I just bolted everything to a piece of plywood for testing purposes. Eventually I will mount it in a weather-proof enclosure. The little perf-board in the lower center with the ICs and other bits on it is the actual controller circuit. The silver bracket below it holds two buttons that allow me to manually toggle the unit between charging batteries and dumping power to a secondary load. The big, black heat sink on the lower left has two 40 Amp blocking diodes bolted into it. I am only using one right now, but I could easily add a second wind turbine or even a photovoltaic solar panel to the system using the second one. The double row of gold rectangles across the top is a dummy load made up of high-Wattage resistors. It has taps at 2 Ohm intervals. I use it as a secondary load to dump power from the turbine into when the battery is fully charged. I also use it for testing purposes to load test the turbine. Eventually excess power from the turbine will be dumped to something more useful like a water heater or a second battery bank. Below and to the left of the dummy load is the main fuse for the wind turbine. The small gray cube is a 40 Amp SPDT automotive relay (the only part I had to purchase) which sends the turbine power either to the batteries or to the dummy load. Along the right side is the terminal block which allows me to connect everything together. In operation, the wind turbine is connected to the controller. Lines then run from the controller to the battery. All loads are taken directly from the battery. If the battery voltage drops below 11.9 volts, the controller switches the turbine power to charging the battery. If the battery voltage rises to 14 volts, the controller switches to dumping the turbine power into the dummy load. There are trimpots to adjust the voltage levels at which the controller toggles back and forth between the two states. I chose 11.9V for the discharge point and 14V for the fully charged point based on advice from lots of different web sites on the subject of properly charging lead acid batteries. The sites all recommended slightly different voltages. I sort of averaged them and came up with my numbers. When the battery voltage is between 11.9V and 14V, the system can be switched between either charging or dumping. A pair of push buttons allow me to switch between states anytime, for testing purposes. Normally the system runs automatically. When charging the battery, the yellow LED is lit. When the battery is charged and power is being dumped to the the dummy load, the green LED is lit. This gives me some minimal feedback on what is going on with the system. I also use my multimeter to measure both battery voltage, and turbine output voltage. I will probably eventually add either panel meters, or automotive-style voltage and charge/discharge meters to the system. I'll do that once I have it in some sort of enclosure. I used my variable voltage bench power supply to simulate a battery in various states of charge and discharge to test and tune the controller. I could set the voltage of the power supply to 11.9V and set the trimpot for the low voltage trip point. Then I could crank the voltage up to 14V and set the trimpot for the high voltage trimpot. I had to get it set before I took it into the field because I'd have no way to tune it up out there. Update: I am now using 14.8V for the full charge point after further researching the proper charging of lead-acid batteries. I have also switched to sealed lead-acid batteries because I got a bunch of them free from my brother. I am contemplating switching to deep-cycle batteries when the ones I have now begin to fail. Update: I have found out the hard way that it is important with this controller design to connect the battery first, then connect the wind turbine and/or solar panels. If you connect the wind turbine first, the wild voltage swings coming from the turbine won't be smoothed out by the load of the battery, the controller will behave erratically, the relay will click away wildly, and voltage spikes could destroy the ICs. So always connect to the battery(s) first, then connect the wind turbine. Also, make sure you disconnect the wind turbine first when taking the system apart. Disconnect the battery(s) last.  Update: Finally, by very popular demand, I have a schematic of my charge controller. Click on it for the full size schematic. It only varies a little bit from the one at the above link. I substituted a few parts I had on hand for ones in the original design. That way I only had to buy a few things to build the controller. You could do the same. It is not critical to exactly duplicate this design. I used a different op-amp chip and a different MOSFET than the original design. Most of the resistor values are not critical. If you have the knowledge to do so, feel free to substitute. Also, feel free to experiment. I'd be interested in hearing from anyone who feels they have improved on the design in any way. Update: Finally, by very popular demand, I have a schematic of my charge controller. Click on it for the full size schematic. It only varies a little bit from the one at the above link. I substituted a few parts I had on hand for ones in the original design. That way I only had to buy a few things to build the controller. You could do the same. It is not critical to exactly duplicate this design. I used a different op-amp chip and a different MOSFET than the original design. Most of the resistor values are not critical. If you have the knowledge to do so, feel free to substitute. Also, feel free to experiment. I'd be interested in hearing from anyone who feels they have improved on the design in any way.At last, all parts of the project were complete. It was all done only a week before my vacation arrived. That was cutting it close. I disassembled the turbine and carefully packed the parts and the tools I'd need to assemble it for their trip across the country. Then I once again I drove out to my remote property in Arizona for a week of off-grid relaxation, but this time with hopes of having some actual electricity on the site.  The first order of business was setting up and bracing the tower. After arriving at my property and unloading my van, I drove to the nearest Home Depot (about 60 miles one way) and bought the 10 foot long piece of 1 1/4 inch conduit I needed for the tower. Once I had it, assembly went quickly. I used nylon rope to anchor the pole to four big wooden stakes driven in the ground. Turnbuckles on the lower ends of each guy-line allowed my to plumb up the tower. By releasing the line from either stake in line with the hinge at the base, I could raise and lower the tower easily. Eventually the nylon line and wooden stakes will be replaced with steel stakes and steel cables. For testing though, this arrangement worked fine. The first order of business was setting up and bracing the tower. After arriving at my property and unloading my van, I drove to the nearest Home Depot (about 60 miles one way) and bought the 10 foot long piece of 1 1/4 inch conduit I needed for the tower. Once I had it, assembly went quickly. I used nylon rope to anchor the pole to four big wooden stakes driven in the ground. Turnbuckles on the lower ends of each guy-line allowed my to plumb up the tower. By releasing the line from either stake in line with the hinge at the base, I could raise and lower the tower easily. Eventually the nylon line and wooden stakes will be replaced with steel stakes and steel cables. For testing though, this arrangement worked fine.  This photo shows a closeup of how the guy-lines attach near the top of the tower. I used chain-link fence brackets as tie points for my guy-lines. The fence brackets don't quite clamp down tightly on the conduit which is smaller in diameter than the fence posts they are normally used with. So there is a steel hose clamp at either end of the stack of brackets to keep them in place. This photo shows a closeup of how the guy-lines attach near the top of the tower. I used chain-link fence brackets as tie points for my guy-lines. The fence brackets don't quite clamp down tightly on the conduit which is smaller in diameter than the fence posts they are normally used with. So there is a steel hose clamp at either end of the stack of brackets to keep them in place. This photo shows the base of the tower, staked to the ground, and with the wire from the wind turbine exiting from the Tee below the conduit tower. I used an old orange extension cord with a broken plug to connect between the turbine and the controller. I simply cut both ends off and put on spade lugs. Threading the wire through the tower turned out to be easy. It was a cold morning and the cord was very stiff. I was able to just push it through the length of the conduit tower. on a warmer day I probably would have had to use a fishtape or string line to pull the cord through the conduit. I got lucky. This photo shows the base of the tower, staked to the ground, and with the wire from the wind turbine exiting from the Tee below the conduit tower. I used an old orange extension cord with a broken plug to connect between the turbine and the controller. I simply cut both ends off and put on spade lugs. Threading the wire through the tower turned out to be easy. It was a cold morning and the cord was very stiff. I was able to just push it through the length of the conduit tower. on a warmer day I probably would have had to use a fishtape or string line to pull the cord through the conduit. I got lucky. This photo shows the turbine head installed on top of the tower. I greased up the pipe on the bottom of the head and slid it into the top of the conduit. It made a great bearing, just as I'd planned. Sometimes I even amaze myself. This photo shows the turbine head installed on top of the tower. I greased up the pipe on the bottom of the head and slid it into the top of the conduit. It made a great bearing, just as I'd planned. Sometimes I even amaze myself. Too bad there was nobody around to get an Iwo Jima Flag Raising type picture of me raising the tower up with the head installed. Now I'm just waiting for the wind to blow. Wouldn't you know it, it was dead calm that morning. It was the first calm day I had ever seen out there. The wind had always been blowing every other time I had been there. Well, nothing to do but wait.  Finally! The wind was up and the turbine was spinning. The winds were actually unusually light the whole time I was on my property this time. The wind turbine still made good amounts of power though, even with winds that at best made it to only a little over 20 mph at times. Finally! The wind was up and the turbine was spinning. The winds were actually unusually light the whole time I was on my property this time. The wind turbine still made good amounts of power though, even with winds that at best made it to only a little over 20 mph at times.This photo shows the controller, battery and associated electronics all wired up. I have a 120V inverter connected to the battery and a multimeter to keep track of the battery voltage and wind turbine output voltage. Also my electric shaver and battery charger are plugged into the inverter and running off of 120V AC. Later I plugged a long extension cord into the inverter and stretched it back to my camp site. I know this setup is really messy, but I was in a hurry to get up and running to take advantage of the wind once it started blowing. That's my excuse, and I'm sticking to it.  This photo is a closeup of the electronics. The meter shows that the wind turbine is producing 13.32 Volts. My electric shaver and battery charger are providing loads on the system through the AC inverter. This photo is a closeup of the electronics. The meter shows that the wind turbine is producing 13.32 Volts. My electric shaver and battery charger are providing loads on the system through the AC inverter. Here the meter shows the turbine producing 13.49 volts. The voltage from the turbine goes up only a little as the wind speed increases once it has a load to power. Once the wind starts blowing, the turbine head snaps around into it and begins spinning up. It spins up quickly until the output voltage exceeds the battery voltage plus the blocking diode drop (around 13.2 volts, depending on the state of the battery charge). it is really running without a load until that point. Once the that voltage is exceeded, the turbine suddenly has a load as it begins dumping power into the battery. Once under load, the rpms only slightly increase as the wind speed increases. More wind means more current into the battery which means more load on the generator. So the system is pretty much self-governing. I saw no signs of over-reving. Of course in storm-force winds, all bets are off. Switching the controller to dump power into the dummy load did a good job of braking the turbine and slowing it way down even in stronger gusts. Actually shorting the turbine output is an even better brake. It brings the turbine to a halt right now, even in strong winds. Shorting the output is how I made the turbine safe to raise and lower, so I wouldn't get sliced and diced by the spinning blades. Warning though, the whole head assembly can still swing around and crack you hard on the noggin if the wind changes direction while you are working on these things. So be careful out there. Here the meter shows the turbine producing 13.49 volts. The voltage from the turbine goes up only a little as the wind speed increases once it has a load to power. Once the wind starts blowing, the turbine head snaps around into it and begins spinning up. It spins up quickly until the output voltage exceeds the battery voltage plus the blocking diode drop (around 13.2 volts, depending on the state of the battery charge). it is really running without a load until that point. Once the that voltage is exceeded, the turbine suddenly has a load as it begins dumping power into the battery. Once under load, the rpms only slightly increase as the wind speed increases. More wind means more current into the battery which means more load on the generator. So the system is pretty much self-governing. I saw no signs of over-reving. Of course in storm-force winds, all bets are off. Switching the controller to dump power into the dummy load did a good job of braking the turbine and slowing it way down even in stronger gusts. Actually shorting the turbine output is an even better brake. It brings the turbine to a halt right now, even in strong winds. Shorting the output is how I made the turbine safe to raise and lower, so I wouldn't get sliced and diced by the spinning blades. Warning though, the whole head assembly can still swing around and crack you hard on the noggin if the wind changes direction while you are working on these things. So be careful out there.  Eventually I decided my setup was too messy and dangerous. Having high current electrical connections and a rat's nest of wires on an Aluminum table wasn't smart. The danger of a spectacular short circuit was too high, so I neatened things up. I set all the electronics on a piece of plywood on top of a plastic storage bin and neatened up the wiring. Then I ran a long extension cord from the inverter back to my camp site and plugged all my stuff into it there. Eventually I decided my setup was too messy and dangerous. Having high current electrical connections and a rat's nest of wires on an Aluminum table wasn't smart. The danger of a spectacular short circuit was too high, so I neatened things up. I set all the electronics on a piece of plywood on top of a plastic storage bin and neatened up the wiring. Then I ran a long extension cord from the inverter back to my camp site and plugged all my stuff into it there.  Here is a longer view of the complete setup. Here is a longer view of the complete setup.  How sweet it is! I have electricity! Here I have my laptop computer set up and plugged into the power provided by the inverter, which in turn is powered by the wind turbine. I normally only have about two hours of battery life on my laptop. So I don't get to use it much while I'm camping. It comes in handy though for downloading photos out of my camera when its memory card gets full, making notes on projects like this one, working on the next great American novel, or just watching DVD movies. Now I have no battery life problems, at least as long as the wind blows. Besides the laptop, I can also now recharge all my other battery powered equipment like my cell phone, my camera, my electric shaver, my air mattress pump, etc. Life used to get real primitive on previous camping trips when the batteries in all my electronic stuff ran down. How sweet it is! I have electricity! Here I have my laptop computer set up and plugged into the power provided by the inverter, which in turn is powered by the wind turbine. I normally only have about two hours of battery life on my laptop. So I don't get to use it much while I'm camping. It comes in handy though for downloading photos out of my camera when its memory card gets full, making notes on projects like this one, working on the next great American novel, or just watching DVD movies. Now I have no battery life problems, at least as long as the wind blows. Besides the laptop, I can also now recharge all my other battery powered equipment like my cell phone, my camera, my electric shaver, my air mattress pump, etc. Life used to get real primitive on previous camping trips when the batteries in all my electronic stuff ran down. So how much did all this cost to build? Well, I saved all the receipts for everything I bought related to this project.

Future modifications and enhancements I would like to make to the system include: